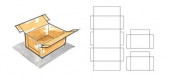

Click to Enlarge

The three pieces of a rigid box style include two identical end panels and a body that folds to form the two side panels, an unbroken bottom and the top. Flaps used to form the joints can be on the end pieces or the body or both. The end panels are attached to the body with special equipment, usually at the user’s plant. Six or more joints must be sealed to set up the box before it is filled. The name Rigid Boxes comes from the fact that once the six or more joints are sealed, the box is rigid. The International Fibreboard Case Code identifies these styles as Rigid-Type Boxes. In the carrier classifications, rigid boxes are classified as Conventional Slotted Boxes or Recessed End Boxes.